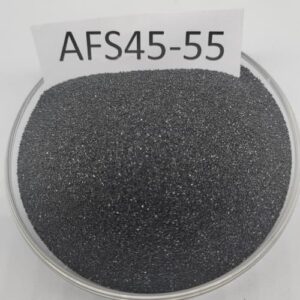

Chromite sand AFS50 for metallurgical sector

Chromite Sand AFS50 is a high-purity, chemically stable refractory sand specifically engineered for the rigorous demands of the metallurgical sector, particularly in foundry operations. Its unique properties make it an indispensable material for producing high-integrity, defect-free castings from both ferrous and non-ferrous metals.

This premium-grade chromite sand is characterized by its excellent thermal conductivity, which promotes rapid and uniform cooling of castings. This significantly reduces the risks of veining, penetration, and burn-on defects, leading to superior surface finish and dimensional accuracy. Furthermore, its high fusion point and exceptional resistance to thermal shock ensure stability even when in contact with high-temperature molten metals, preventing sintering and minimizing mold wall movement.

Origin: South Africa

CHEMICAL&PHYSICAL PROPERTIES OF Chromite sand AFS50 for metallurgical sector

| Cr2O3 | ≥46.0% |

| SiO2 | ≤1.0% |

| FeO | ≤26.5% |

| CaO | ≤0.30% |

| MgO | ≤10.0% |

| Al2O3 | ≤15.5% |

| P | ≤0.003% |

| S | ≤0.003% |

| Cr/Fe | 1.55:1 |

| Bulk Density | 2.5-3g/cm3 |

| Color | Black |

| PH | 7-9 |

| The amount of the acid | ≤ 2 ML |

| Percent soil | ≤0.1 |

| Percent Moisture | ≤0.1 |

| The sintered | 1600℃ |

| Percentage of free acid present in the sand | 0 |

| Filling density | 2.6g/cm3 |

| Sintering point | > 1,800℃ |

| Melting temperature | 2,180℃ |

Reviews

There are no reviews yet.