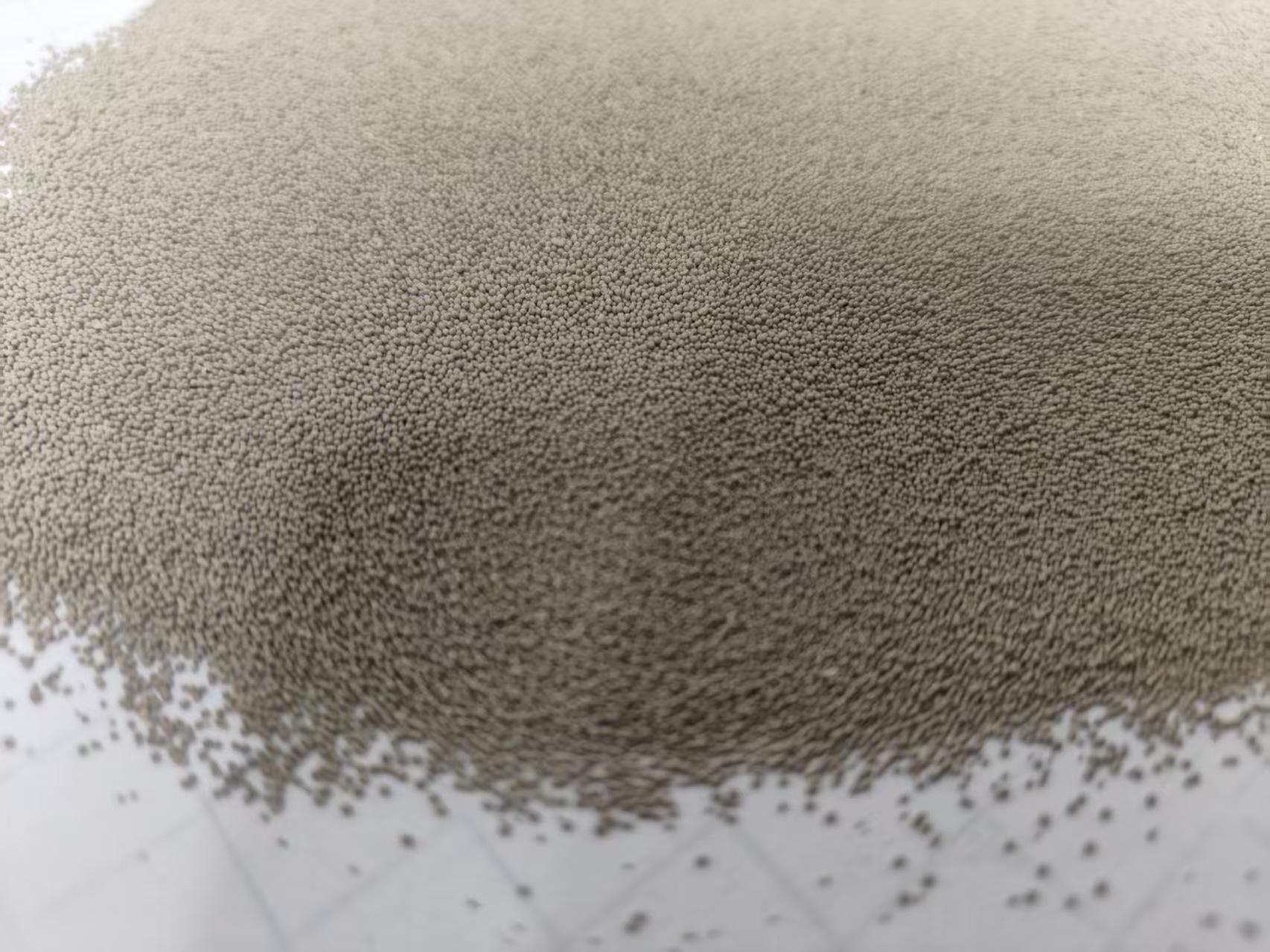

Ceramic sand for resin coated sand and thermal reclamation sand

PRODUCT: Ceramic Foundry Sand

NAME: Ceramic Foundry Sand Al2O3 CONTENT: 70% MIN.

DESCRIPTION:

This new developed specific Foundry Sand is produced by bauxite from the special selected high quality refractory raw material at very high temperature at 2,300 – 2,500℃. Our these ACFS sand has excellent solid cores with high strength and very low resin addition rates. The materials has excellent crystalline with formula is 5Al2O3-SiO2.

TYPICAL CHEMICAL ANALISIS [%]:

| Al2O3 | Fe2O3 | SiO2 | FeO | MgO | CaO | TiO2 | Na2O | K2O | LOI |

| 70-73 | 0.3max | 20 | / | / | / | 3.5max | / | / | < 0.09 |

PHYSICAL PROPERTIES:

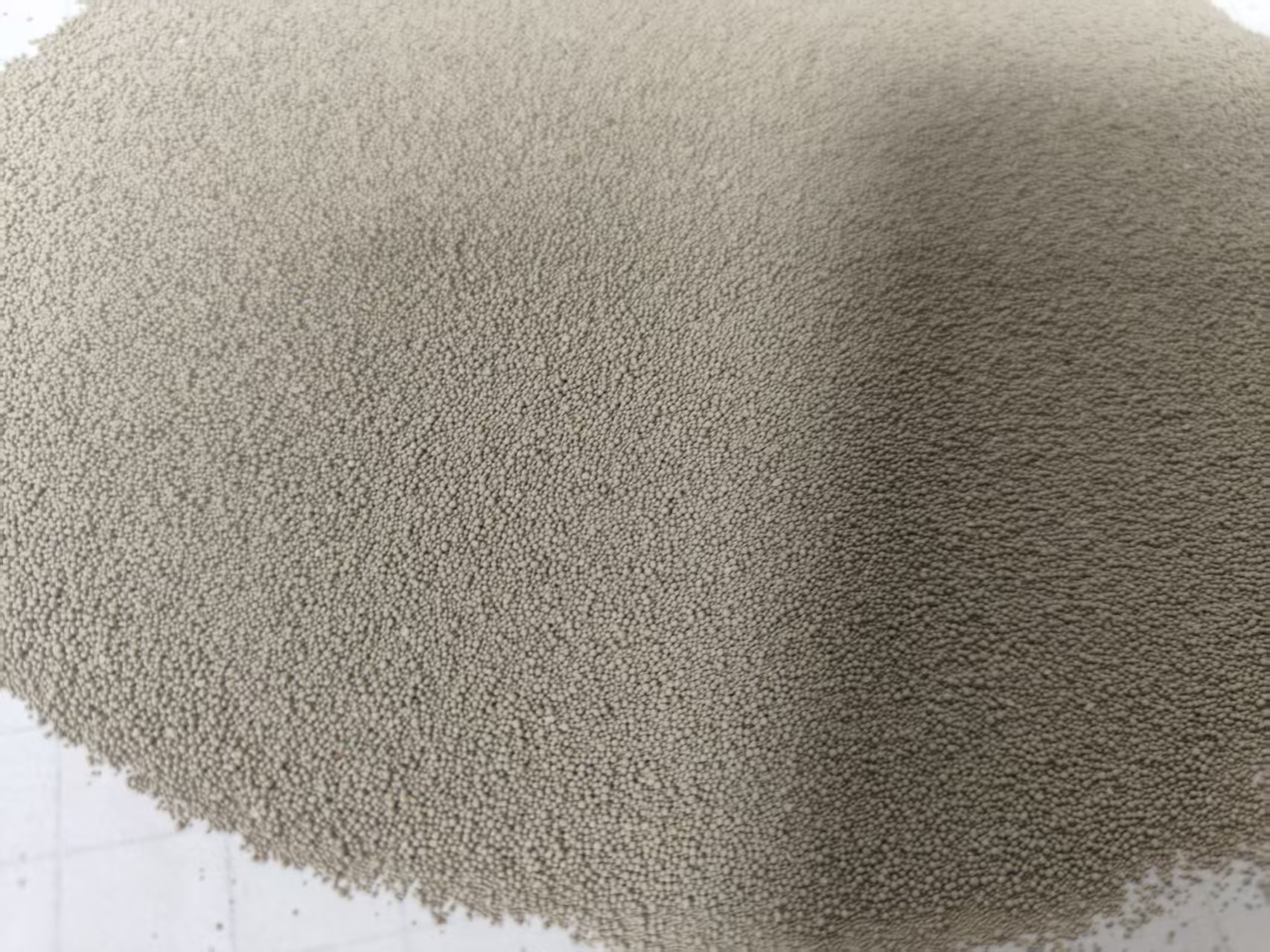

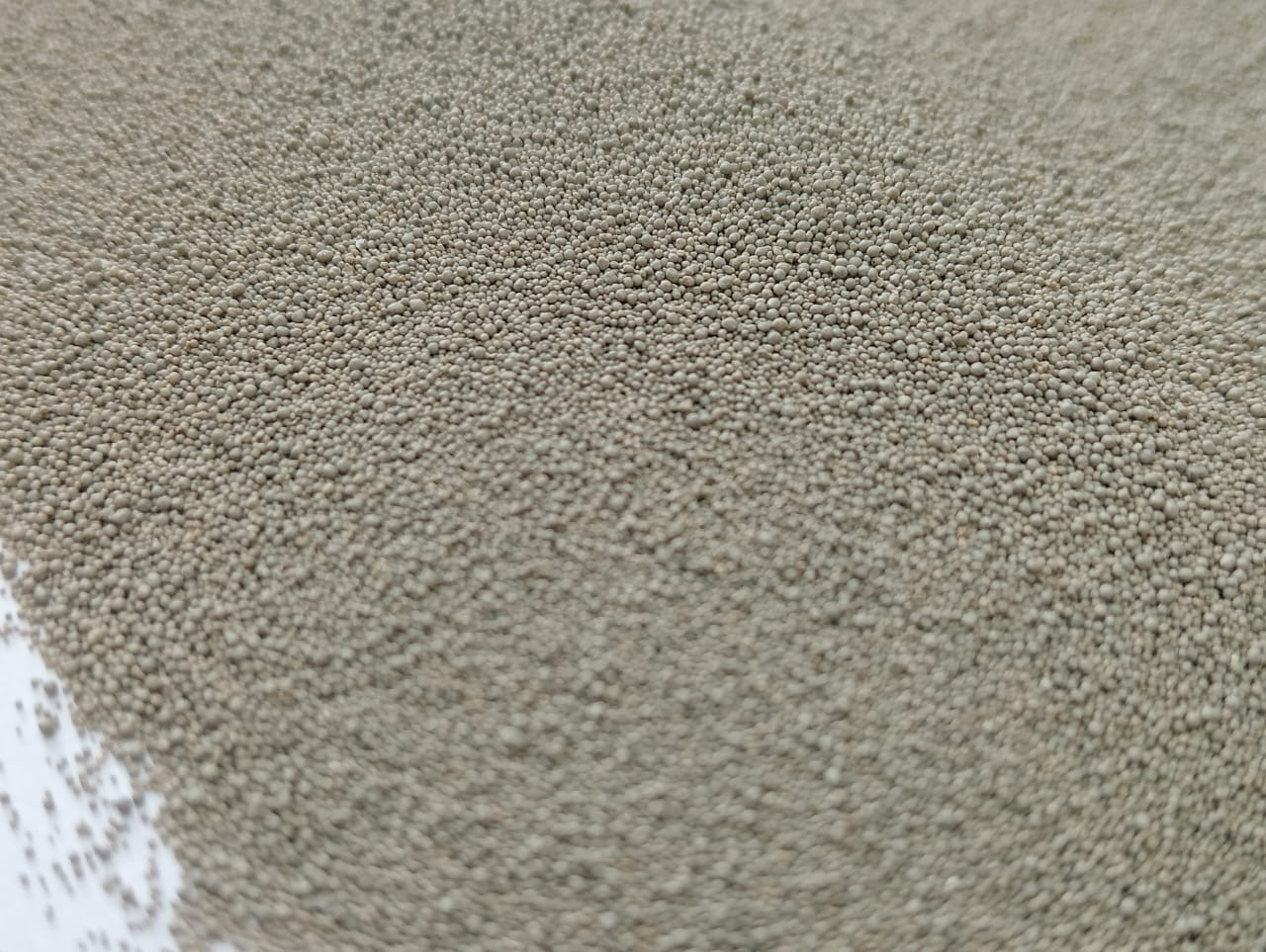

Shape:ball, spherical

Angularity: 1.1 max, similar to ball Bulk Density:1.95-2.05(g/cm3) Refractoriness: 1790 C min

Thermal expansion: 0.13% (10 min at 1000 C )

SIZE:

AFS25-35; AFS25-30; AFS30-35; AFS35-40; AFS40-45; AFS45-50; AFS40-50; AFS50-55; AFS55-60; AFS60-65.

MOSTLY USED AS :

Waterglass bonded sand

Resin bonded sand precision casting Expendable Pattern Casting (EPC) Copper and Aluminium articles casting treatment.

Carbon Steel and Alloy Steel: Beaded sand is suitable for alloy steel castings such as high-manganese steel and high-chromium cast iron, as well as ordinary carbon steel castings. It prevents metal penetration and sand adhesion, improving surface quality.

Cast Iron and Copper: In the production of non-ferrous metal castings such as cast iron and copper, beaded sand can reduce casting defects and improve dimensional accuracy.

For large and complex castings such as diesel engine water assemblies, machine tools, pumps and valves, and hydraulic components, beaded sand overcomes the shortcomings of traditional molding sand, such as high expansion coefficient and high binder requirements, thereby improving yield.

High-Precision Castings: Beaded sand’s spherical particles and low thermal expansion coefficient (0.13%) make it an ideal material for manufacturing high-precision castings such as aircraft engines and spacecraft components.

Ladle Drainage Sand: The high refractory properties and chemical stability of jelly sand make it suitable for ladle drainage sand, improving molten steel pouring efficiency.

Electronic equipment castings, such as heat sinks and housings, require jelly sand to meet the high precision and surface quality requirements of electronic equipment.

Corrosion-resistant and high-temperature-resistant chemical equipment: Jelly sand’s excellent chemical stability makes it suitable for manufacturing corrosion-resistant and high-temperature-resistant chemical equipment castings.

PACKING:

25kgs Pvc bags+1MT big bag